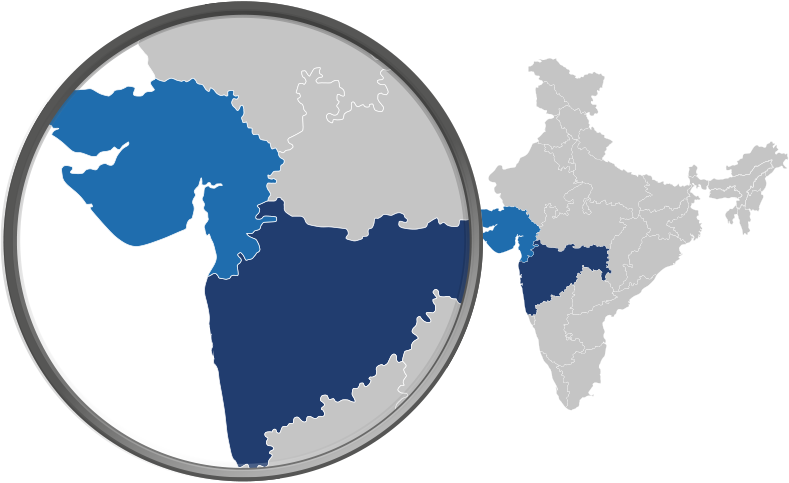

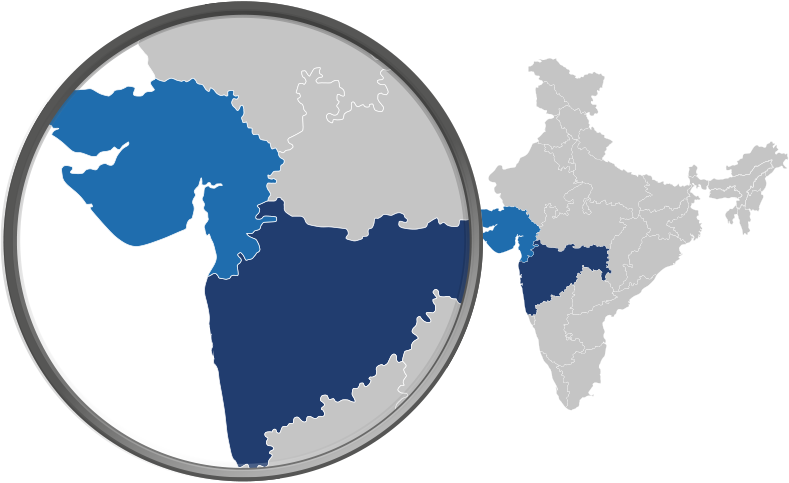

Locations

Our Head Office is located in Mumbai, India’s commercial capital and the largest city in the western region.

HEAD OFFICE:

Mumbai

SITES:

Dombivli, Vapi, Tarapur, Atali

PORTS NEAR OUR SITES:

Kandla, Nhava Sheva, Hazira, Dahej

Our Head Office is located in Mumbai, India’s commercial capital and the largest city in the western region.

Mumbai

Dombivli, Vapi, Tarapur, Atali

Kandla, Nhava Sheva, Hazira, Dahej

This facility has R&D centre along with a manufacturing unit with approximately 30,000 litres reactor capacity. R&D is equipped with fume hoods, RBF, autoclaves, flow reactors, and other equipment. It also has a process engineering lab and a lab for process safety.

This unit is capable of handling the following reactions:

The facility has six manufacturing blocks aligned with more than 125 reactors (SS reactors, GLR reactors, hydrogenator) with a combined capacity of 550,000 litres. It is engaged in the manufacturing of intermediates, Regulatory Starting materials (RSM) required for API and NCEs. The operations of this unit are in the hands of extremely skilled personnel who ensure adherence to quality systems and procedures.

The unit is capable of handling the following reactions:

| Authority | Date of Audit |

|---|---|

| USFDA | Approved since June 2010 |

| ISO | ISO 9001:2015 Certified since 2011 Latest successful inspection in March 2016 |

| ISO | ISO 45001:2018 Last date for migration was by 31 March, 2021 |

| ISO | ISO 14001: 2015 |

It specialises in the manufacture of xanthine derivatives including caffeine, theophylline, etofylline and aminophylline. The facility, with a workforce more than 170 trained personnel, is equipped with SS reactors, GLR reactors, and PP reactors with capability of approximately 300 metric tonnes per month.

This unit is capable of handling the following reactions:

This state-of-the-art API facility has 5 manufacturing blocks with a competence for gram-to multi kilo scale synthesis and manufacturing.

Manufacturing Block No. 1 : General API and NCE

Manufacturing Block No. 2 : Cortico Steroids API (Dedicated)

Manufacturing Block No. 3: Oncology API (Dedicated)

Manufacturing Block No. 4: General API and NCE

Manufacturing Block No. 5: General API and NCE

The blocks in the facility are aligned with 75 reactors (SS reactors, GLR reactors & PVDF reactors) with a combined capacity of 225,000 litres.

The unit is capable of handling the following reactions:

| Authority | Date of audit |

|---|---|

| USFDA | Approved for the first time in March 2008 Approved for the second time in September 2011 Approved for the third time in March 2015 Approved for the fourth time in December 2016 Latest approval in February 2020 |

| EU-GMP | Approved by Danish Medicines Agency in April 2008 Approved by Freie und Hansestadt Hamburg May 2012 Approved by Freie und Hansestadt Hamburg in Aug 2013 Approved by Freie und Hansestadt, Hamburg in Jan 2015 |

| ISO | ISO 9001: 2000 certified since April 2006 Latest successful inspection in August 2015 |

| WHO-GMP | WHO GMP certified since Oct 2006 Latest successful inspection in Dec 2015 |

| ISO | ISO 14001: 2015 certified since June 2021 |

| ISO | ISO 45001: 2018 certified since June 2021 |

It excels in producing our flagship product “caffeine”. The plant is set up with SS reactors that have a 69,000 litre capacity overall. The institution is run by a staff of 50 people.

The unit is capable of handling Methylation reaction.

It is a pioneer in producing sulphuric acid as well as related goods like liquid sulphur trioxide, oleum 23% and 65%, and sulphonation base products like dimethyl sulphate, diethyl sulphate, and sodium vinyl sulfonate. Dimethyl urea and ammonium sulphate are also produced. With more than 100 staff, the plant is equipped with SS reactors, GLR reactors, catalytic converters, and distillation systems with a daily capacity of about 350 metric tonnes.

This unit is capable of handling the following reactions:

| Authority | Date of audit |

|---|---|

| ISO | ISO 9001:2015, ISO 14001:2015, Certified since 2019 Latest successful inspection in May 2022 |

| ISO | ISO 45001:2018 Certified since 2019 Latest successful inspection in May 2022 |